Back Фоторезист Bulgarian Vernís fotosensible Catalan Fotolack German Fotoresist Estonian لاک نوری Persian Résine photosensible French Fotoresis ID Fotoresist Italian フォトレジスト Japanese Фоторезист Kazakh

A photoresist (also known simply as a resist) is a light-sensitive material used in several processes, such as photolithography and photoengraving, to form a patterned coating on a surface. This process is crucial in the electronics industry.[1]

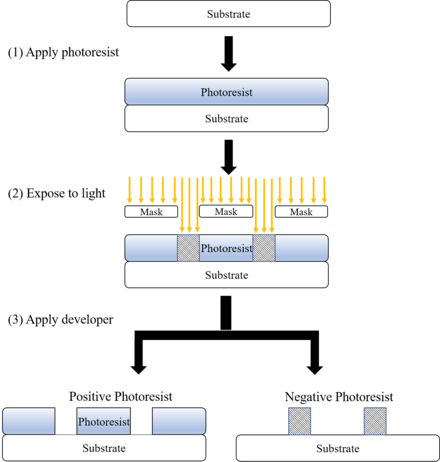

The process begins by coating a substrate with a light-sensitive organic material. A patterned mask is then applied to the surface to block light, so that only unmasked regions of the material will be exposed to light. A solvent, called a developer, is then applied to the surface. In the case of a positive photoresist, the photo-sensitive material is degraded by light and the developer will dissolve away the regions that were exposed to light, leaving behind a coating where the mask was placed. In the case of a negative photoresist, the photosensitive material is strengthened (either polymerized or cross-linked) by light, and the developer will dissolve away only the regions that were not exposed to light, leaving behind a coating in areas where the mask was not placed.

A BARC coating (Bottom Anti-Reflectant Coating) may be applied before the photoresist is applied, to avoid reflections from occurring under the photoresist and to improve the photoresist's performance at smaller semiconductor nodes.[2][3][4]

Conventional photoresists typically consist of 3 components: resin (a binder that provides physical properties such as adhesion, chemical resistance, etc), sensitizer (which has a photoactive compound), and solvent (which keeps the resist liquid).

- ^ Eric, Anslyn; Dougherty, Dennis. Modern physical organic chemistry. University Science Books.

- ^ "Top Anti-reflective Coatings vs Bottom Anti-reflective Coatings".

- ^ MicroChemicals. "Basics of Microstructuring: Anti-Reflective Coatings" (PDF). Microchemicals GmbH. Retrieved 2020-01-31.

- ^ "AR™ 10L Bottom Anti-Reflectant Coating (BARC) | DuPont". dupont.com.

© MMXXIII Rich X Search. We shall prevail. All rights reserved. Rich X Search